1. Installation, debug

We will arrange seasoned technician for debug and test production at the same time make the equipment reach the rated producing

capacity of the line.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. The sample service

(1) We can send you the video of the running machine.

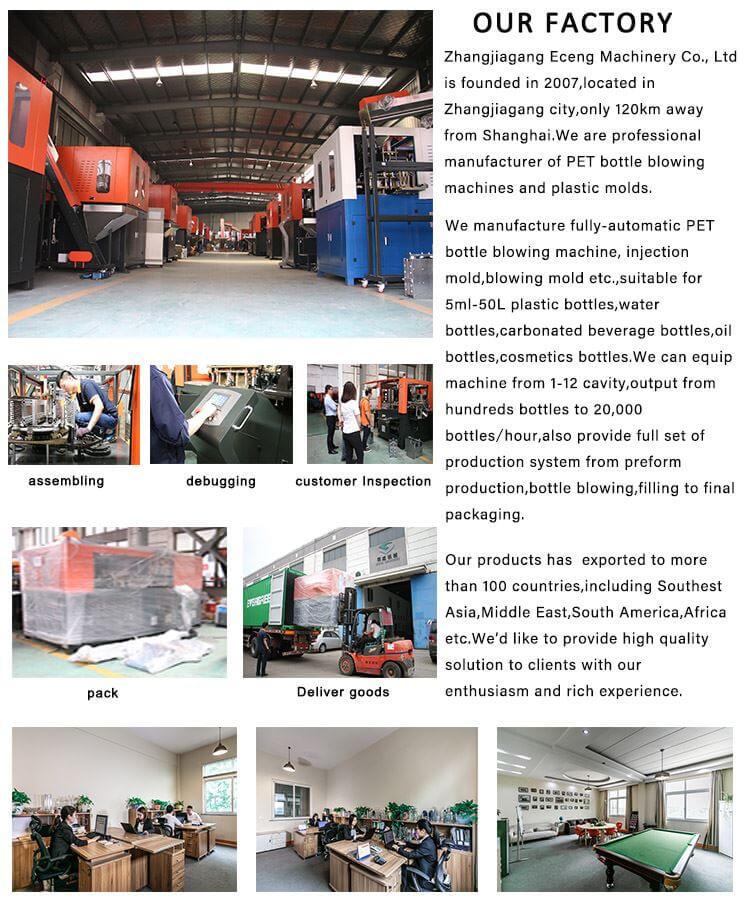

(2) You are welcome to come to visit our factory,and see the machine running.

(3) We can design the machines according your requirements,at the same time we will give you our professional suggestion,as you know,we have been in this industry for 12 years.

(4) Well-trained & experienced staff are to answer all your inquiries in English and Chinese.

(5) 12 Months guarantee and life-long technical support.

(6) Your business relationship with us will be confidential to any third party.

(7) Good after-sale service offered, please get back to us if you got any questions.